Where Products are Built to Last

The consistent use of Prefab Granite/Quartz Countertops products is prevalent for residential and commercial construction projects. Both the product categories offer the amazing look and sturdiness to the interior and exterior of your living space.

As a manufacturer and exporter, we believe in presenting a clear picture of product production process to our global clients with the help of our experienced quality assurance team. Our quality control procedures are enacted by adhering to the buyer’s specifications and minimizing the import risks.

Quality Control practices involve:

-

Pre-production Quality Control

-

During production Quality Control

-

Pre-shipment Quality Control

-

Container Loading Supervision

Necessary Natural Stone quality checks in terms of appearance:

-

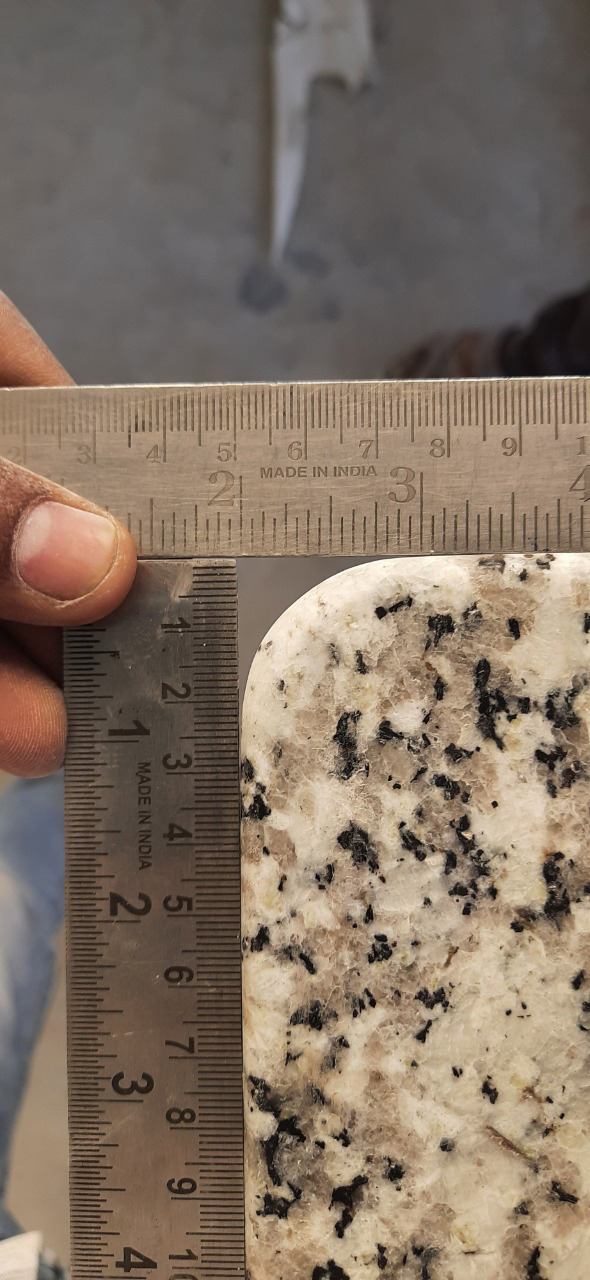

Size Based Specifications: Length, width, and thickness with strength tolerance factor, the diagonal length, angle control, etc.

-

Material Appearance Inspection: Color, texture, spots, lines, grain structure, uniform crystals, etc.

-

Inspecting Defects: Scratches, fissures, repairs, swirl marks, cracks, broken edges, chip edges, pinholes, etc.

-

Finishing Inspection: Polished, antique, honed, bevel edge, lepatora, natural cleft, tumbled, bush-hammered, flamed, etc.

-

Additional Production Process: Degree of polish, flat surface, angle of straight edges.

Quality Inspection as per Global Standards

-

Our experts start working on quality-proven granite & quartz counter tops right before the order confirmation. The order samples are designed to match the buyer’s product requirement in terms of color and pattern. It helps to seek buyer’s approval on pricing before moving ahead with the project. The quality parameters are finalized as per industry standards. Every detail is mentioned in the proforma invoice which further includes buyer’s signature.

-

The order related information is communicated to the production department. Futhermore, the purchase order is shared with the factory unit and branch office staff. The field inspectors who perform the quality checks are also provided with its copy. The quality check staff is well-equipped with various measuring instruments to keep regular checks on products during the production stage.

-

During different stages of production, regular monitoring of products is performed by the branch office. Then, inspection reports are shared with the head office. Order is cancelled at the earliest stage if manufacturing unit is unable to achieve the standard and transferred to another factory.

-

The product images are also forwarded to the head office along with the inspection report. Simultaneously, crate manufacturing process comes into picture and is finalized by the quality inspectors after proper inspection.

-

After the production is done, the field officer performs the process of product sorting and packing. The chief quality officer inspects the material on each quality parameter and final report is submitted to the head office. After the final check and approval, the production manager gives his consent. Consequently, the buyer is communicated with all the details. Every piece of information is shared via mail to maintain record for the subsequent reference.

-

Special inspection is also made available as per the buyer’s requirement.

-

The wooden crates are loaded in the factory premises whereas unloading part is performed at the port. For a record, each and every move is being photographed by the shipment department as one of the mandatory quality check steps. The photographs are shared with the production department by the shipment agent to keep an eye on quality of crates, lashing, and stuffing. Thus, the regular exchange of reports and images within both the departments take place till the products are in perfectly packed condition as per global standards.

We are known for on-time delivery of intact products as per international quality.