Oceanic6 Solutionz is not only about having the right machines to make high-precision granite and quartz countertops, but it also takes the knowledge of the machines, materials, and programming to get the same results for hundreds of pieces. Apart from that, we have the facilities that feature bridge cutters, CNC routers, water jets, multi-head polishing systems, edge profilers, and advanced material handling equipment.

Bridge cutters are the ones that set the basic dimensions for all the countertops. The laser-guided systems along with the diamond blades are the things that make sure the edges are smooth and there is no chipping. By keeping the tolerances within 1-2 mm, problems with the fit of multi-unit project will be prevented.

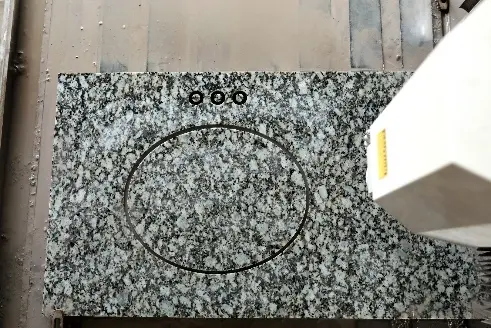

With the use of CNC routers, the tasks which include the cutting out of sinks, making holes for the faucets, grooves for the drains, cutouts for the cooktops, and edge profiling are handled. CAD files are turned into toolpaths which help to make the cuts precise and also the same across the whole batch of units—installation is the one that becomes consistent and easy when there are dozens of units in the batch.

The Waterjet cutting is the process of cutting complex forms by using extremely high-water pressure along with some abrasives. While using a waterjet, the water under high pressure is mixed with some abrasive and then the cutting is done. It goes heat-free hence there is no heat stress on the parts after cutting. It's best for tight-radius curves as well as for inlays and decorative patterns. In addition, it minimizes the microfractures thus finishing the edges becomes easy.

There are many heads and along with that different and more refined grits are used for the polishing. Some of the parameters like the pressure, speed, and water flow are set to the granite or quartz in order to get the same gloss all over and that the surface is free from scratches.

The edge machines take care of the edging providing the consumer with the most common - eased, beveled, bullnose, half-bullnose, ogee, and custom profiles. The uniformity and high quality of the edges are the things that are accomplished by consistent pressure and hand-finishing at corners.

The problem of moving heavy slabs is no longer there when one employs cranes, trolleys, vacuum lifters, and rubber-grip fixtures. Identification markings are used in maintaining the orientation as well as the vein alignment throughout production.

We employ specific solutions for common fabrication issues to maintain the highest quality standards.

| Challenge | Process | Impact | Solution |

|---|---|---|---|

| Blade deflection | Bridge cutting | Dimensional variation | Controlled RPM + reduced feed |

| Vein mismatch on L-shape | Bridge cutting | Visual discontinuity | Digital slab mapping |

| Tool wear | CNC routing | Wrong cutout depth | Auto tool-height calibration |

| Burn marks on quartz | CNC routing | Aesthetic defects | Optimized RPM + multi-pass |

| Tapered cuts | Waterjet cutting | Angled edges | Taper correction + pressure tuning |

| Slow processing | Waterjet cutting | Delays | Waterjet rough + CNC finish |

| Uneven gloss | Surface polishing | Inconsistent finish | Programmable head pressure |

| Swirl marks | Surface polishing | Visible defects | Controlled water flow + grit plan |

| Corner polishing issues | Edge finishing | Quality variation | Template-guided hand polishing |

| Material movement | All ops | Cracks / misalignment | Rubber-grip lifters + crane safety |

Copyright © 2025 Oceanic6 Solutionz. All Rights Reserved.