At Oceanic6 Solutionz, we have one clear commitment: it is the utmost necessity that every granite or quartz piece from us must be the exact match to your approved specifications, not only that but also we need to be able to keep this quality all the time, and furthermore, we have to make sure it is great enough, so it doesn't require any additional work for installation. No matter if it is multi-unit housing, commercial projects, or luxury homes, our tool guarantees quicker and confusion-free installations onsite.

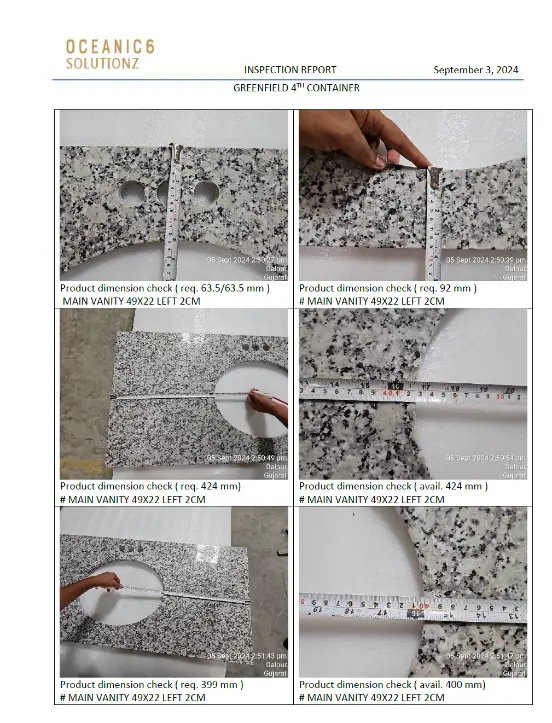

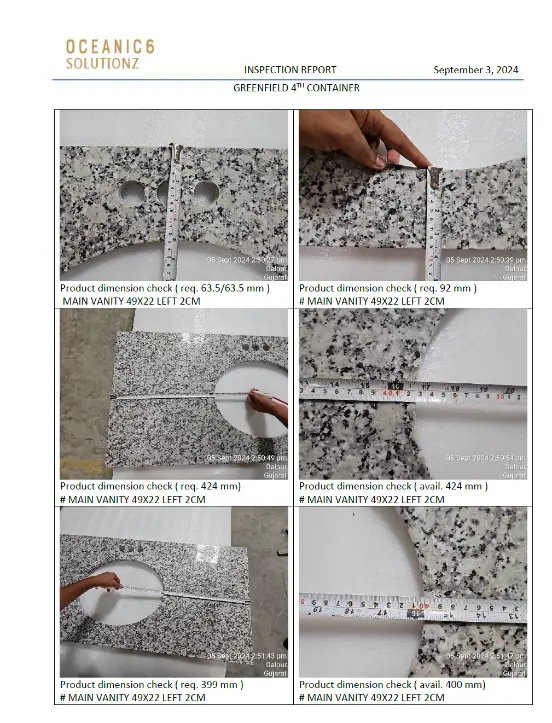

The whole structural system of QC is what each fragment is subjected to and that is in line with the final workshop drawings of yours.

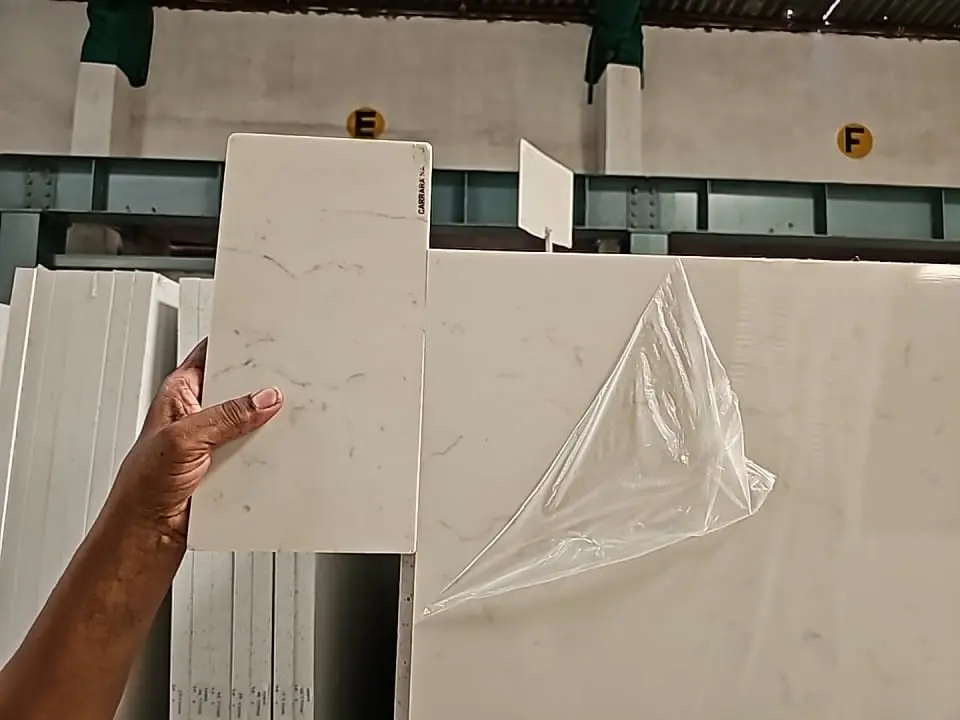

Makes the changes of the color of the pattern and the pattern of the fabric are the standard of the fabric which is utilized both in the shade and the pattern.

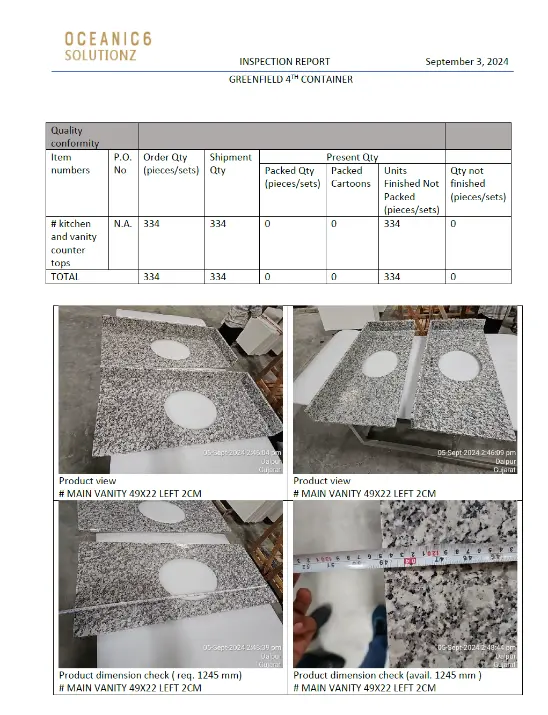

Pieces are monitored to be of the precise thickness.

The inspection for surface finish encompasses the identification of uniformity, the right texture, as well as the absence of processing mark.

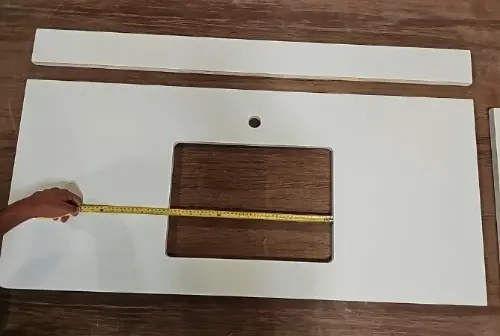

The measures of length, width, and depth are checked against prints.

The correct size, shape, and positioning of all cutouts are ensured.

Ensures the edge detail is correct and consistent.

Confirms that all pieces are correctly marked, which speeds up workflow on large multi-building projects.

Before the goods are shipped, you are provided with a full QC report containing.

If you approve the QC report, the next step will be final packing and container loading. The crates are labeled with detailed manifests, packing lists are added inside and outside, pieces are arranged for easy unloading, and final loading photos as well as seal documents are shared—thus, delivery is made safe, organized, and transparent.

Inspection standards are strict for each and every piece and the pieces correspond to the approved dimensions, color consistency is maintained, and pieces are clearly labeled. Shipping is preceded by full documentation; thus, a customer gets what he approved.

Copyright © 2025 Oceanic6 Solutionz. All Rights Reserved.