Successful granite or quartz countertops at Oceanic6 Solutionz always begin with accurately and professionally engineered shop drawings.

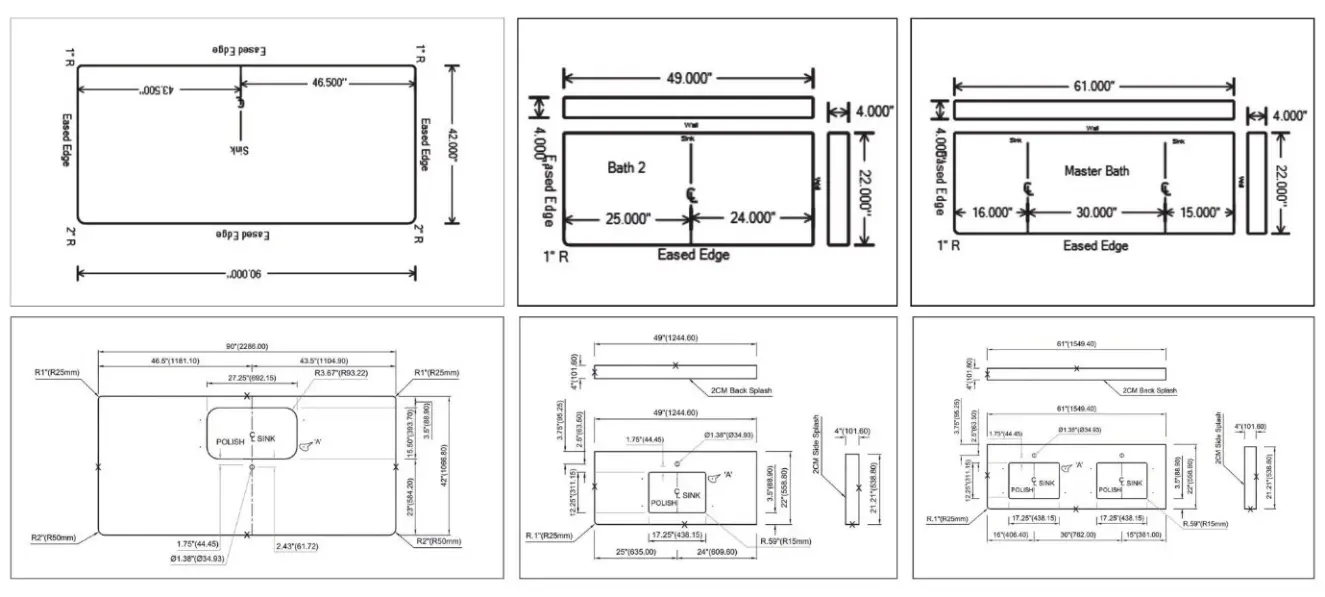

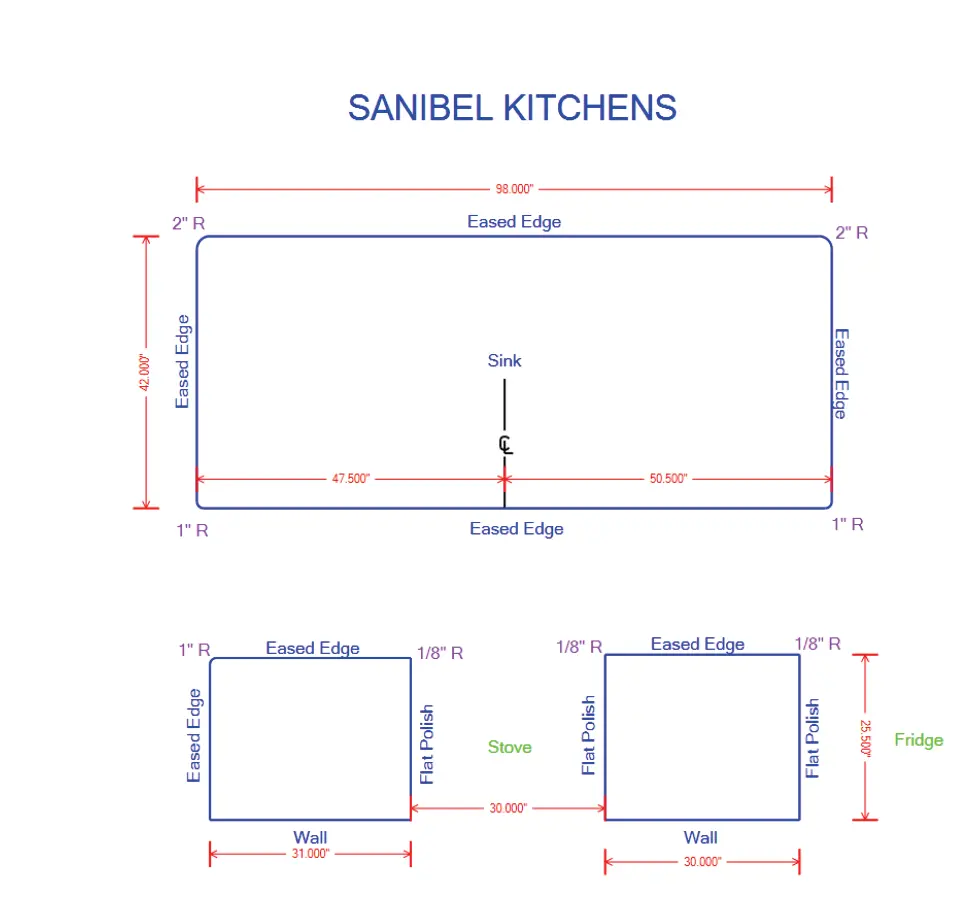

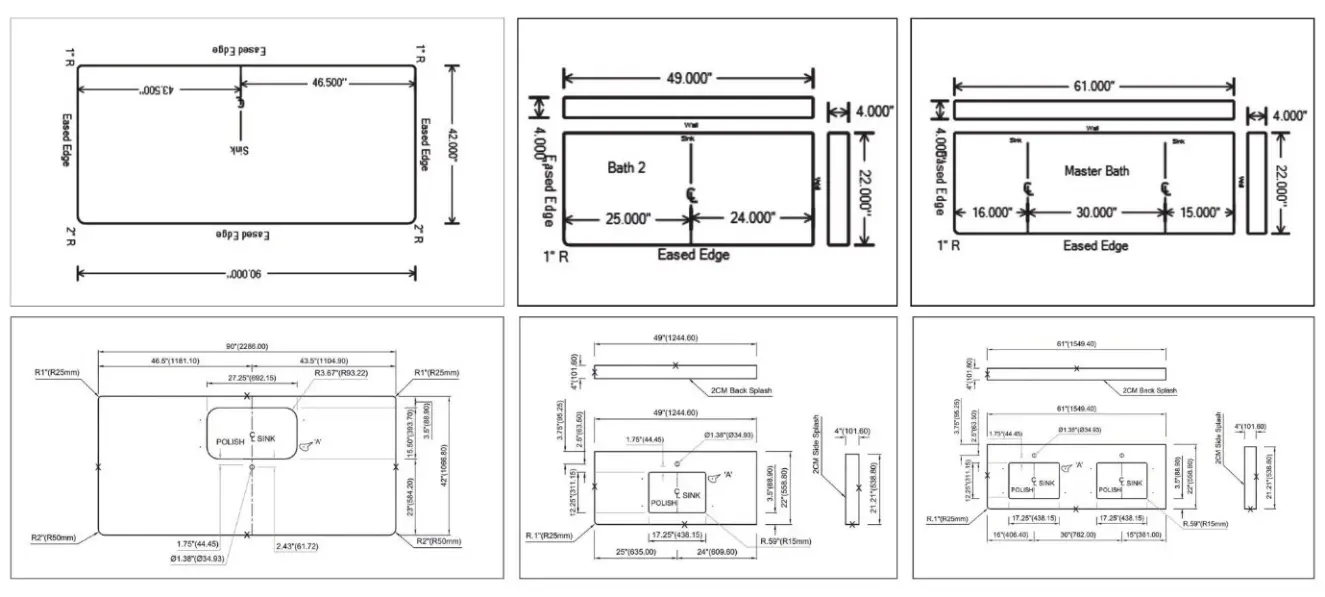

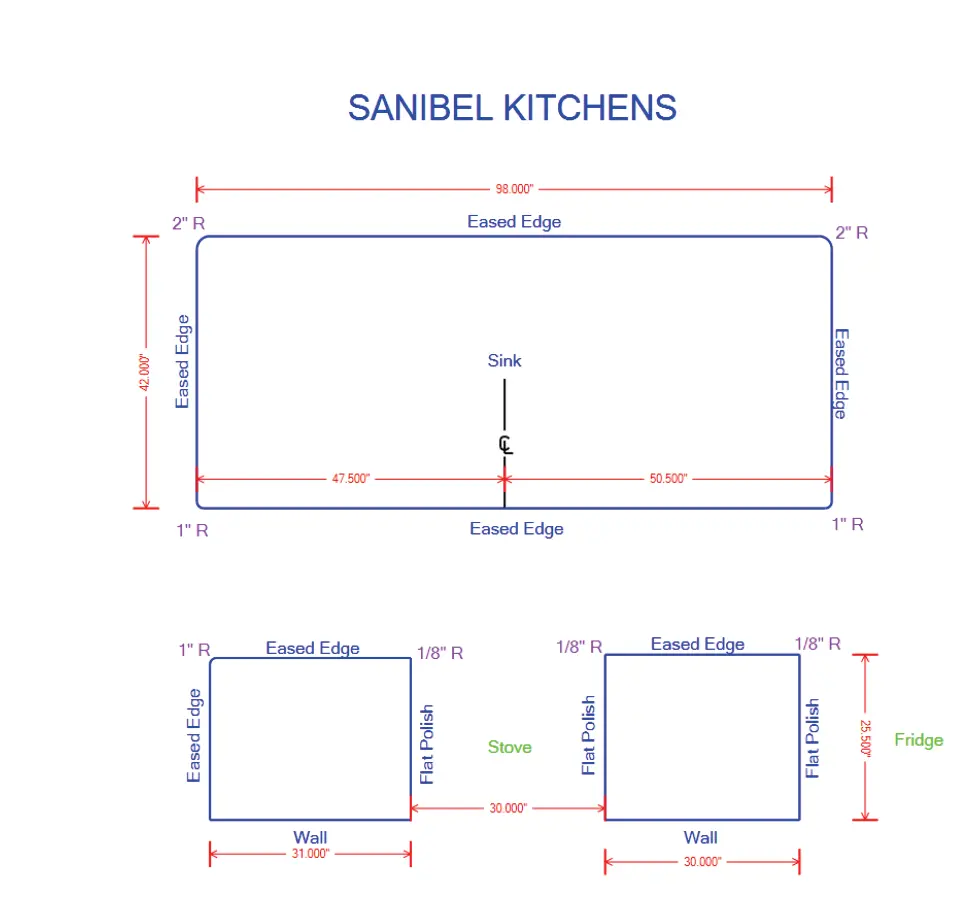

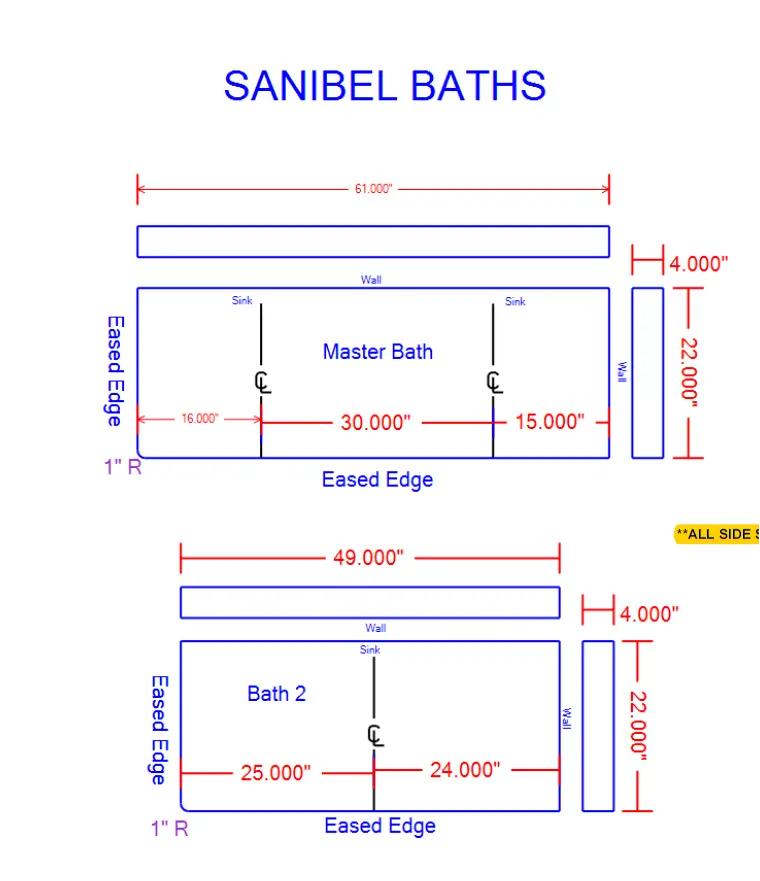

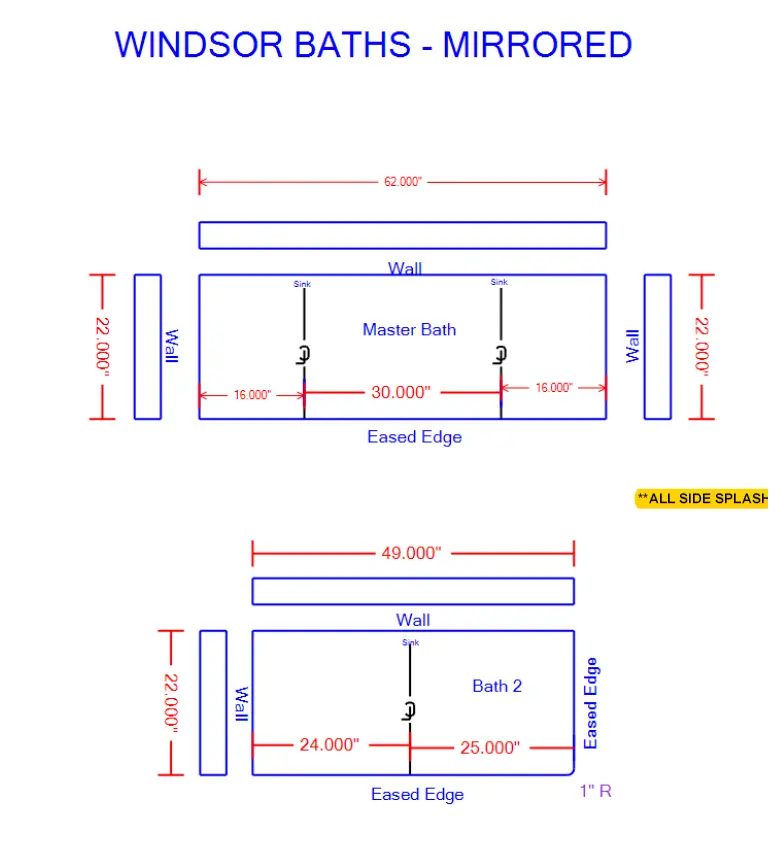

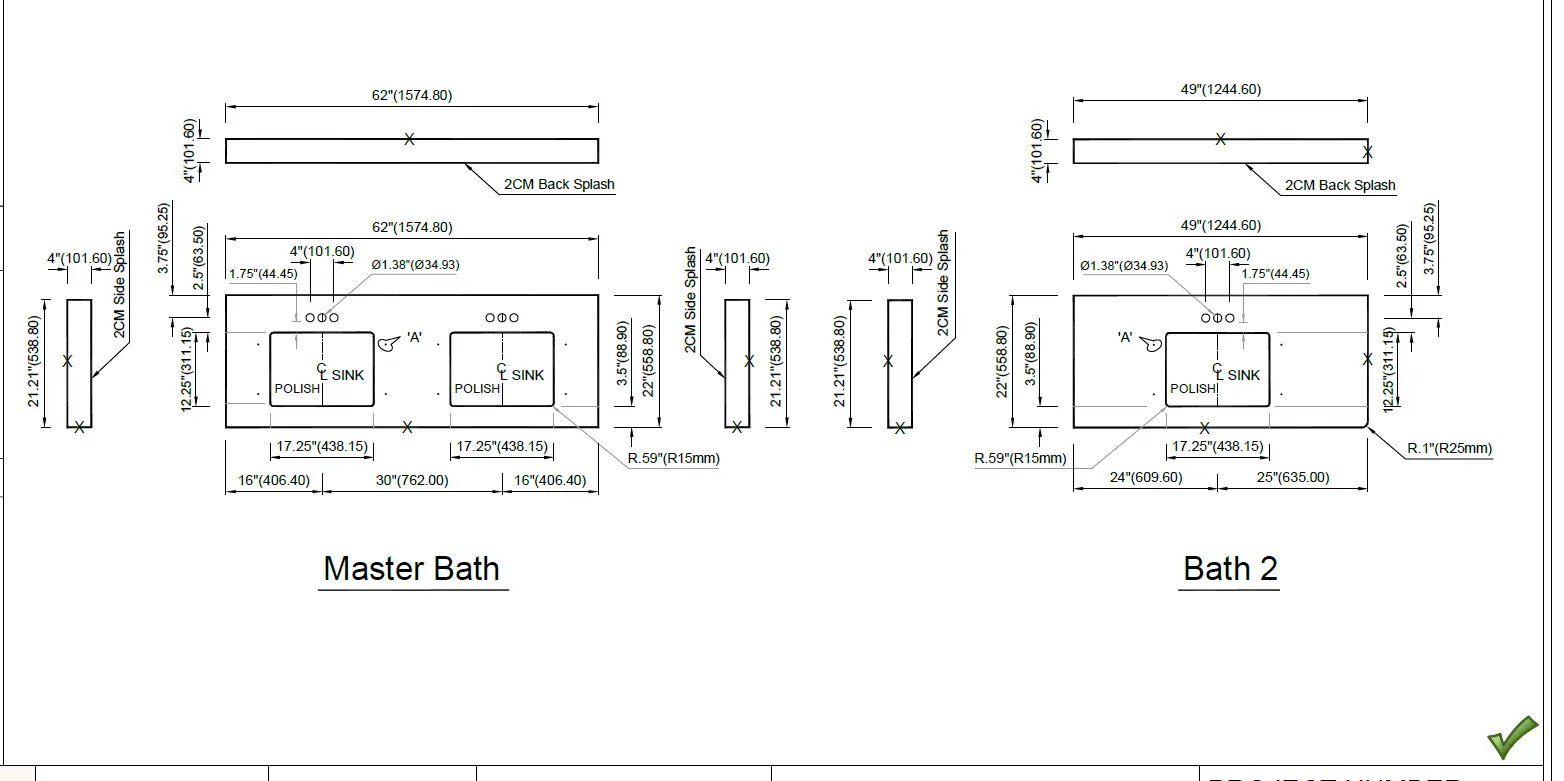

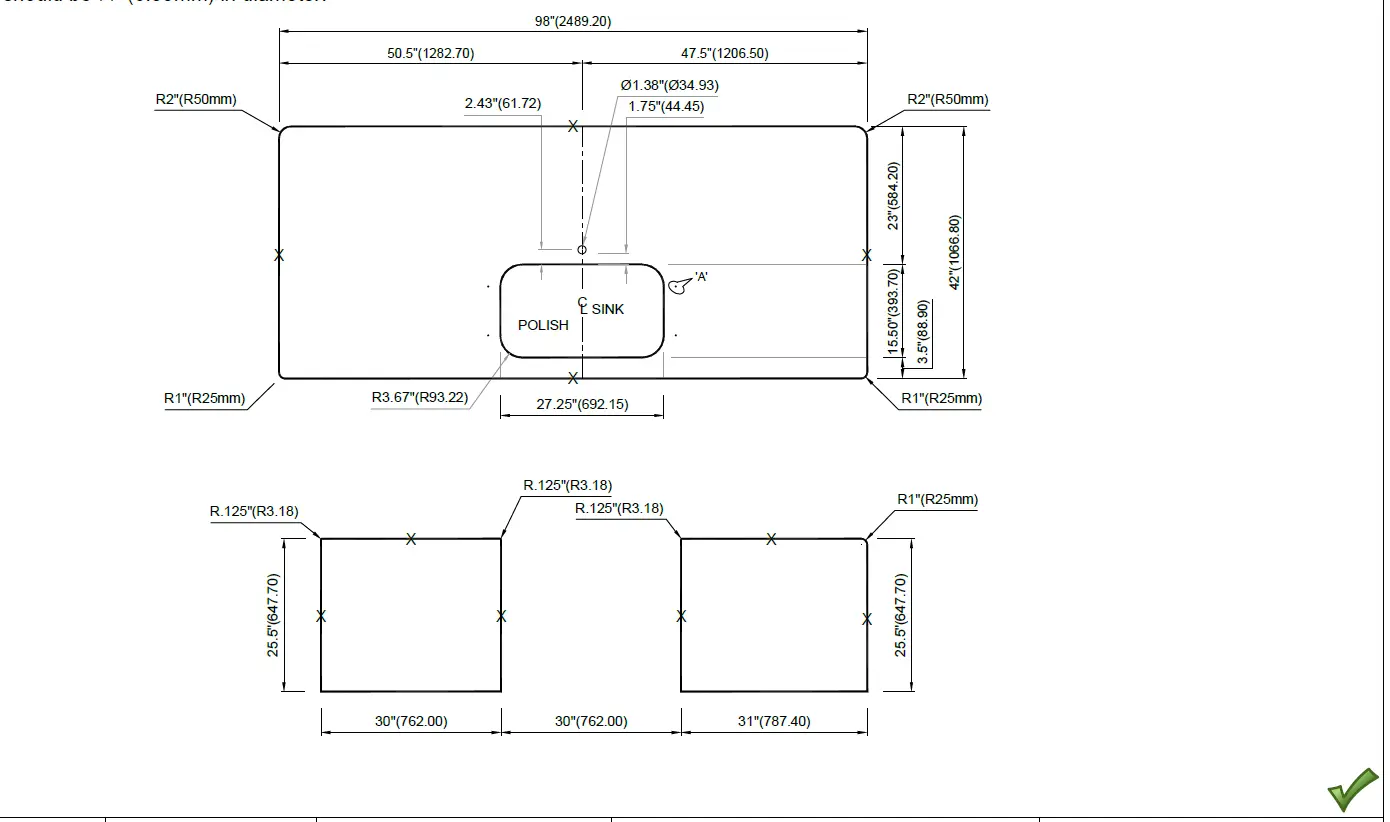

Through CAD design, our team transforms client measurements, site layouts, and sink/cabinet details into exact drawings that are ready for fabrication—thus, assuring installation of the countertop that fits perfectly and eliminating the mistakes that can be quite costly.

We start by going through all the details provided by the client:

We ensure that all the details that are not mentioned or are confusing are explained before we start working.

Our designers produce comprehensive shop drawings that illustrate:

Drawings are provided in PDF format for a quick check and confirmation.

Clients check out the measurements, sink positions, and edge details (all details of project drawing).

If there are any changes, they are done quickly, and the work of fabrication is only started after the final approval.

Our CAD design system ensures predictable, efficient, and successful project outcomes:

Our CAD design is the basis for every countertop project leading to success.

Oceanic6 Solutionz makes sure that the production is without errors and the installation is quick, easy, and exactly up to the client's wishes by concentrating on the precision, good communication, and approval through the system.

Copyright © 2025 Oceanic6 Solutionz. All Rights Reserved.