It is said that a product that has been fabricated in the best way can lose its value if it gets damaged during shipping. Therefore, Oceanic6 Solutionz takes the process of packaging as an essential part of quality control.

Our goal: To be able to deliver every slab and countertop in perfect condition, installation-ready.

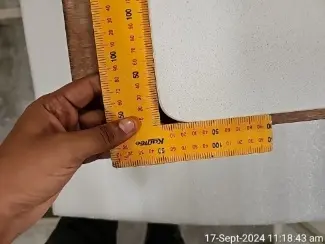

Wrapping each product individually according to its size, weight, and fragility is the way we do it.

We have to ensure that each stone shipment that we prepare is able to fulfill five paramount requirements:

Each piece is visually examined and verified for:

Only the pieces that have been given the green light proceed to packaging.

Every crate is custom-built using heat-treated hardwood and includes:

Crates are engineered to maximize safety and container space.

Each stone piece receives:

This prevents friction, impact, and vibration damage.

Comprehensive Labeling Protocol

A waterproof packing list is placed inside and outside each crate.

Containers are planned for maximum space use and safe unloading.

Years of experience have taught us how to address the challenges inherent in shipping natural stone products:

| Challenge | Our Solution |

|---|---|

| Oversized countertops | Reinforced hardwood crates with extra-thick foam padding and corner protection |

| Extended ocean transit | Waterproof exterior wrapping plus silica gel moisture absorption inside sealed crates |

| Complex projects with many piece types | Color-coded labels and detailed crate contents sheets that list every item |

| Limited container space | Advanced load planning software to design compact crate layouts that maximize fit |

| ISPM 15 compliance requirements | All wood heat-treated and properly stamped with internationally recognized fumigation marks |

| Manual handling risks at destination | 4-way pallets and clearly marked lifting points for safe forklift access |

| Urgent delivery schedules | Additional packing staff assigned to complete large orders without rushing quality |

| Mixed material shipments | Separate crates for granite and quartz with clear material type labels |

At Oceanic6 Solutionz, packaging is a science backed by experience. Whether we ship a single vanity top or hundreds of countertops for a multi-unit project, every crate receives the same professional care.

Strong packaging = Safe delivery = Happy clients.

Copyright © 2025 Oceanic6 Solutionz. All Rights Reserved.