Oceanic6 Solutionz teamed up with a top-tier sub-contractor in Ohio to provide the material and deliver the custom-fabricated China White granite countertops for a sizable senior living housing development.

The scope of the work included the countertops for kitchens, peninsulas, vanities, and common areas in 126 residential units with the specification of tight timelines and ready-for-installation conditions.

The project was finished on time, all the items were completely labeled, and the delivery was made with no defects—thus, fulfilling all the client’s expectations.

| Project Aspect | Details |

|---|---|

| Project Name | China White Cut-to-Size Installation |

| Project Type | Multi-Unit Senior Living Housing |

| Location | Miamisburg, Ohio, USA |

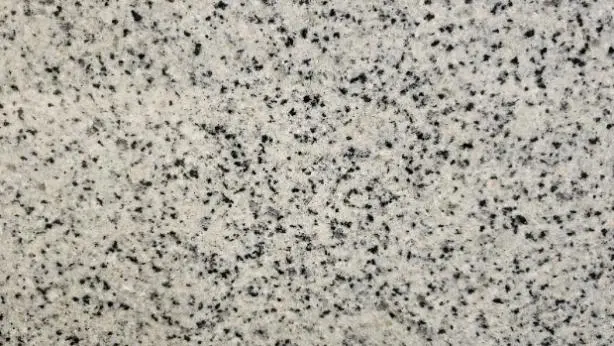

| Material | China White Granite (Natural Stone) |

| Surface Finish | High-Polish with Eased Edge Profile |

| Thickness | 30mm (Kitchens), 20mm (Vanities) |

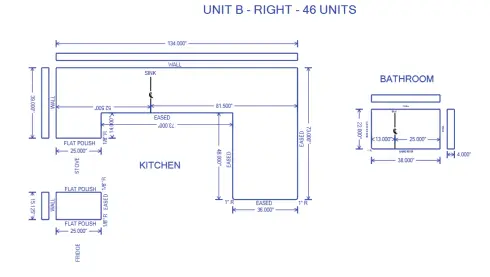

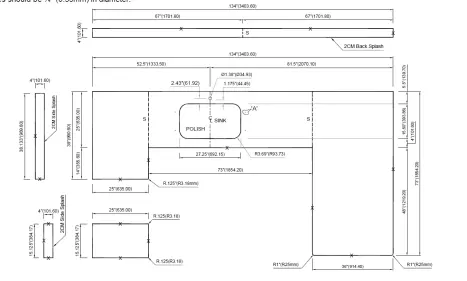

| Backsplash and Sidesplash Configuration | 4-inch Height |

| Sink Installation | Undermount Single Bowl |

| Total Square Footage | 6,845 sq. ft. |

| Number of Units | 126 Residential Units |

| Shipping Volume | 3 Full 20-foot Containers |

| Delivery Terms | DDP (Door-to-Door Delivery) |

We were able to achieve this large-scale project in a mere 51 days from the time of approval to the final delivery due to our streamlined fabrication process.This efficiency is our result of the long way we've been through handling multi-unit residential installations.

| Phase | Process Details | Duration |

|---|---|---|

| Design Approval | CAD shop drawings created per specifications | 1–2 days |

| Fabrication | Cutting, polishing, finishing, quality control, packaging | 15 days |

| Shipping | Ocean freight plus door delivery to job site | 36 days |

| Total Duration | Complete project timeline starts to finish | 51 days |

Based on the client's cabinet finishes and the overall interior theme, our design team suggested appropriate color options. Material samples were made and sent for inspection to make sure the selected material was in line with the project vision. Only after the client's confirmation was the manufacture initiated.

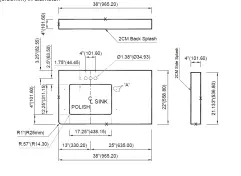

For each of the 126 units, our design team developed comprehensive CAD shop drawings illustrating the measurements, cutouts, and installation details These drawings were discussed with the client, and the green light was given before the fabrication to ensure that the installation would fit perfectly.

The fabrication involved precise cutting, polishing, and finishing as per the approved shop drawings. Every piece was carved to its exact size, including accurate sink cutouts, edges, and splashes.This resulted in a perfectly fitting and visually consistent set of countertops for all 126 units.

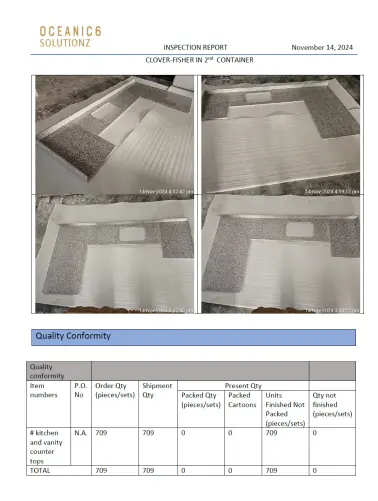

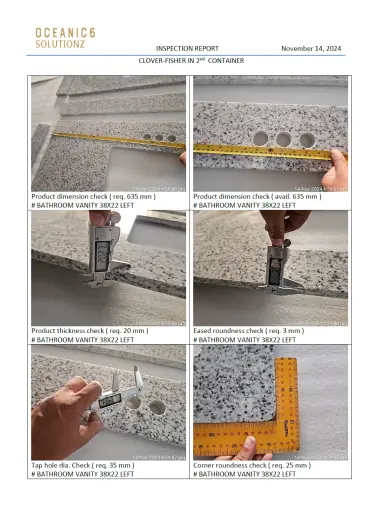

Every single item was subjected to multi-stage inspections, checking:

A full QC report along with photographs was given to the client before loading the goods.

Each countertop was packed with:

A Detailed Labeling System ensured organized delivery

This meticulous process ensured zero damage during long-distance transport.

For safe and efficient handling: Crates were placed on 4-way forklifting pallets and weight distribution was meticulously planned. Load plans and pictures were sent to the client. DDP delivery made sure the client got everything right at their work location—without delays.

Copyright © 2025 Oceanic6 Solutionz. All Rights Reserved.